Foresee/Longsys Industrial Memory Cards to Address Four Major Pain Points of Vehicle Monitoring Market

Recording interruption, stopping, and frame loss; recording stops frequently on multi-channel monitoring systems; cards often get stuck when being inserted or removed; video loss and card damage

This is a Press Release edited by StorageNewsletter.com on June 30, 2023 at 2:01 pmMonitoring equipment should be able to record continuously without compromising on image quality and integrity, especially in automotive applications, as video evidence is extremely important in many scenarios.

Foresee, a brand of Shenzhen Longsys Electronics Co., Ltd. company, is committed to providing professional product solutions and storage services to address the pain points of the industry and create value for customers. In this issue, the company will focus on the market performance of memory cards in vehicle monitoring equipment and introduce the storage application characteristics and industry pain points in this field from multiple perspectives.

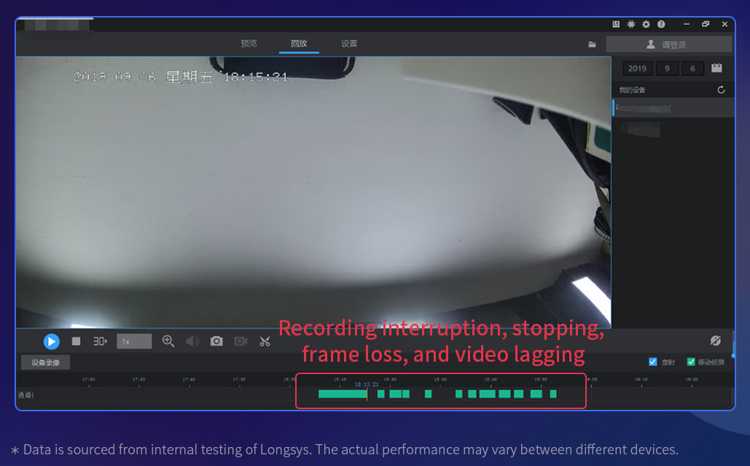

Pain point 1: Recording interruption, stopping, and frame loss

These are the most nerve-wracking problems for end customers and they are closely related to the memory cards equipped on the devices. When selecting memory cards for their monitoring equipment, customers usually prioritize writing speed according to the bit rate of their devices. However, memory cards on the market are often marked with their highest reading and writing speeds, not their minimum performance.

To avoid recording interruption, stopping, and frame loss in practice, the minimum speed of the memory card must also meet the bit rate requirements of the device. Therefore, the minimum speed should be the key factor in determining a memory card’s suitability for a recording device.

Recording interruption, stopping, and frame loss

By optimizing the firmware architecture and intelligent garbage collection (GC) technology, the memory card R&D team of the firm has improved the performance smoothness to ensure that the reading and writing speeds can meet bit rate requirements in any extreme environment and that the vehicle monitoring system can run stably.

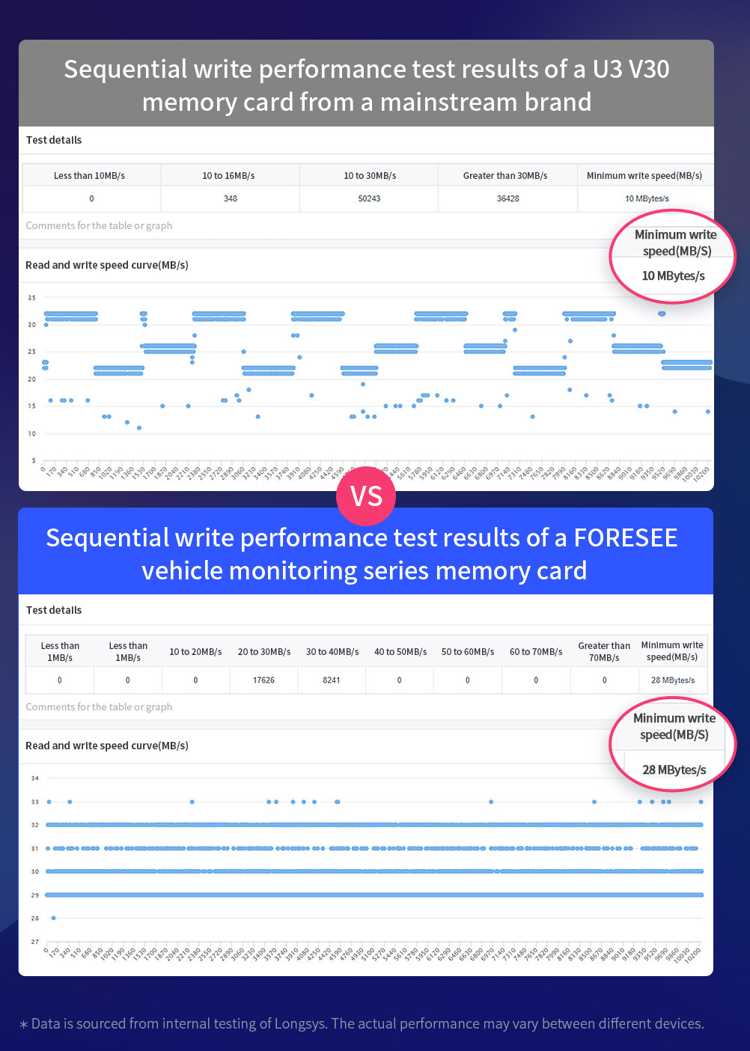

The performance of different brands for the same card type is also quite different. Take the U3 V30 memory card as an example. The average performance of the company’s industrial SD/microSD cards ranges between 28 to 33MB/s, the minimum performance can reach 28MB/s, and the overall performance is smooth under the same test conditions (SDIO CLK 100MHz).

Sequential write performance test

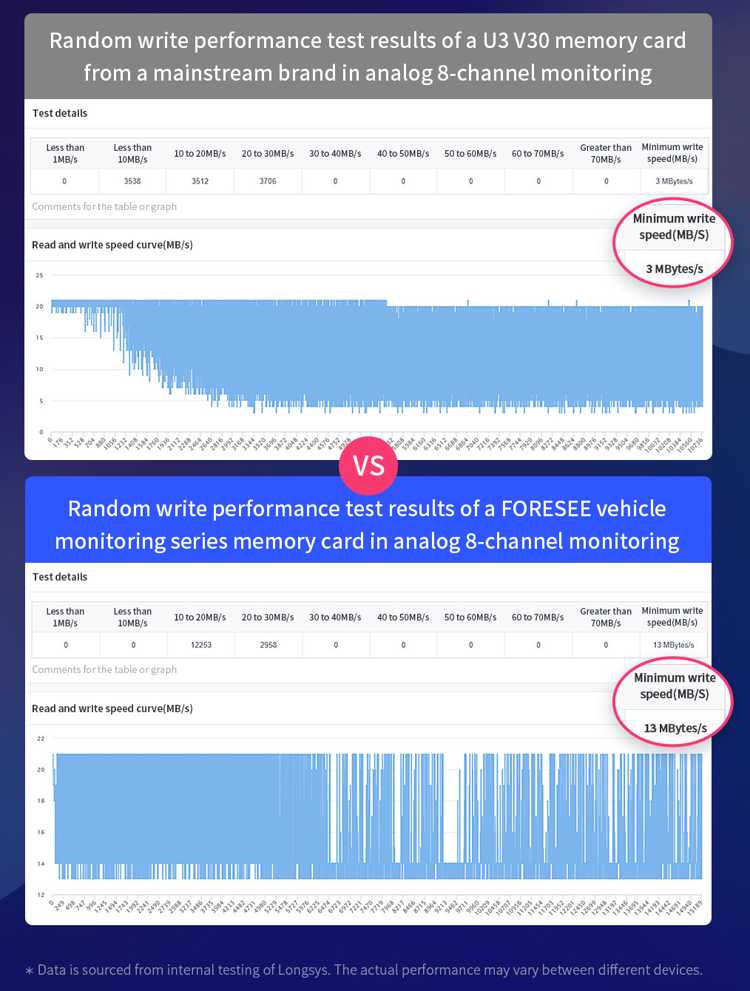

Pain point 2: Recording stops frequently on multi-channel monitoring systems

4-channel and 8-channel cameras have become popular with the rapid development of vehicle monitoring. Although the total bit rate of recorded vehicle monitoring videos is not large, the random R/W performance of memory cards still face great challenges as the storage of multi-channel monitoring must be able to handle random address writing and small file writing for AI behavior monitoring.

Multi-channel monitoring stops recording

As use time increases, the fragmentation of the memory card will become more and more serious, and the GC pressure will also increase. This may eventually cause the memory card to fail to meet the bit rate requirements, resulting in recording stopping and frame loss. The firm’s memory cards optimize the multi-channel management mechanism and leverage the intelligent GC algorithm, which reduces data fragmentation and improve speed stability to avoid the above problems.

Except for the unavoidable random write speed fluctuations in multi-channel cameras, the company’s industrial SD/microSD cards maintained a minimum write speed above 13MB/s and performed well in the random write stress test under the condition of analog 8-channel cameras (SDIO CLK 50MHz).

Random write performance test

Pain point 3: Cards often get stuck when being inserted or removed

To reduce the impact of driving vibrations on equipment contacts, connector manufacturers have introduced anti-vibration slots with self-locking functions for vehicle-mounted application scenarios. However, the cards often get stuck when being inserted or removed due to the design of such a slots.

To address this issue and provide solutions, the firm’s memory card team has established a dedicated microSD production line and conducted a comprehensive analysis of the pain points and difficulties of memory cards.

Pain point 4: Video loss and card damage

Like all electronic products, memory cards have a limited lifespan. As videos are not frequently retrieved from vehicle monitoring systems, users may find that their memory cards have reached the end of life when they finally want to retrieve videos, and may not be able to do so.

To allow users to actively monitor the health of their storage, the company’s memory card team has opened the S.M.A.R.T information interface to vehicle monitoring systems. This allows users to monitor the health status of the card at any time and receive early warnings before the lifespan is over, and it can all be done in a visualized way.

Memory card lifespan visualization

New dimension for vehicle monitoring storage

Traditional mechanical storage is being replaced by flash storage products due to the increasing performance requirements of vehicle systems as well as other challenges during vehicle operation, such as temperature and vibration. Therefore, vehicle devices with excellent SD/microSD cards and SSDs have attracted more attention from end customers.

In the future, the company will continue to explore the field of vehicle storage and launch storage products that better suit market applications.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter