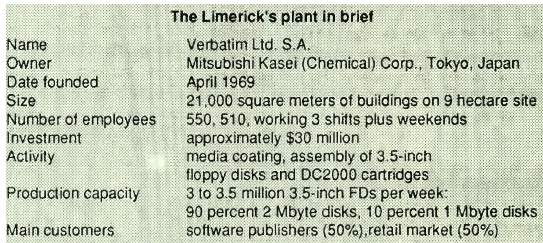

History (1994): Report on Verbatim Factory in Limerick Ireland

Largest floppy disk plant in Europe

By Jean Jacques Maleval | February 10, 2021 at 2:17 pmThe cracked and crumbling tarmac of the two-lane road running from Cork to Raheen Industrial Estate on the outskirts of Limerick presents a sharp contrast to the ultra-modern Verbatim factory.

Inside one of the floppy disk plant’s 3 buildings, 7 assembly lines run parallel from one end of an enormous, clean room to the other. Each line is capable of putting out one floppy disk per second.

“It is the largest flexible disk plant in Europe,” said Mark Dargan, product marketing and operations support manager.

Mechanization is pushed to the limits here and the few employees intervene only when a robot breaks down

Three levels of quality assembly ends with a certification zone where all of the disks are verified in a Sony or Teac floppy drive turning at twice the speed of a normal device in order to test the disk in 45s.

A line of 46 such drives are fed automatically by one robot able to push in and pull out 46 disks in a single motion. As a result, the products are sorted according to the quality met: very good (corresponding to a clip level above 70%), good (52 to 70%), and failing (less than 52%). The ECMA standard is from 40%, while the theoretical limit is 90%. 70% is the level demanded by software publishers.

Dargan did not offer an exact number of rejected disks, but indicated that it is less than 5%.

Disks meeting less than 52% are run though the control line a second time and are discarded upon failure. To reopen them and add the necessary components from the assembly line would be too costly.

Packaging is equally automatic with, for example, a machine capable of wrapping 300,000 FDs per day.

The only manual labor is a small group working on a special promotional line launched, for a limited period of time, by Verbatim’s Italian subsidiary.

Media produced on site Limerick plant produces its own magnetic media that alone is more costly than the dozen other components of a floppy disk. Each fabricator creates its own mixture of about 20 different ingredients at Verbatim, that results in a layer of approximately 30 microns covering the 2 faces of a polyester roller in which the finished media circulars are punched.

Part of this production is destined for other Verbatim factories WW and another part is sold directly to Asian resellers.

Other elements of the disks are furnished by outside suppliers, mostly from the surrounding area, and are closely controlled by Verbatim.

A subcontractor in Dublin is responsible for the shells, using molds made by Verbatim for plastic injection. The shutters come from England, where they are fabricated with Verbatim tools.

One of 8 Verbatim factories in the world, Limerick is one of only 3 to produce the coating, along with Sunnyvale, CA, and Odawara, Japan.

The latter is the only manufacturer of 4MB disks, targeted for the Japanese market as they have not been successful elsewhere. Other assembly plants are located in Australia, in US (West Virginia and North Carolina) and in Mexico. Verbatim’s total production is estimated at around 500 million FDs per year globally, 150 million from the Limerick plant, not including those purchased from subcontractors.

The company makes up for about 18% of the world market for 3.5-inch disks.

“We have the largest European market share in the critical OEM market,” said Dargan.

This year, Limerick abandoned production of 5.25-inch FDs, 19 years after their debut, when it was transferred to Mexico. Since August, this activity has been replaced by assembly of QIC DC2000 cartridges with components shipped from Tijuana, Mexico, previous supplier for Europe.

The demand for floppy disks in Europe remains significant. In an attempt to meet this need, the Limerick plant operates 24 hours a day, 7 days a week, with 3 8-hour shifts daily.

In Ireland, Verbatim enjoys the advantage of a “non-unionized flexible educated workforce permitting maximum flexibility.“

Average salaries are also less than in continental Europe. Nevertheless, this is hardly comparable to Mexico where salaries are nearly 5x lower, but extreme robotization at the Limerick plant provides partial compensation.

After the disk? What media will follow the relative low capacity one then 2MB diskettes?

“It will be magneto-optical disks,” says Dargan, citing Mitsubishi’s team of 380 people in optical disk research as proof.

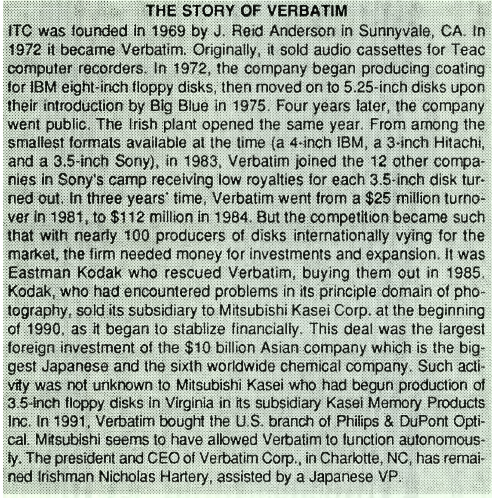

Confirming its interest in computer media, Mitsubishi Kasei bought out the US arm of PDO in 1991, then Carlisle in 1992. This did not, however, prevent Verbatim, world leader in optical media, from producing 20MB Floptical drives for Insite Peripherals, or from listing SunDisk flash cards in its catalog.

Last July, Limerick stopped assembly of 3.5-inch 1MB disks, now shipped from US to meet the European demand.

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue 81, published on October 1994.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter