History (1993): IBM Giant Magneto-Resistance to Store 1Gb Per Square Inch on HDDs

Or 30x density of current media

By Jean Jacques Maleval | November 2, 2020 at 2:10 pmAdStar (San Jose, CA), a business unit from IBM, has revealed a new technology called “giant magneto-resistance” to store up to 10Gb per square-inch on a magnetic HDD, 30 times the density of actual media.

Here is the description of the new method, according to a document from AdStar.

Their scientists have discovered a new method of producing the phenomenon called “giant magneto-resistance”. Their method may make it possible, by the end of the decade, to store up to 10Gb of information in a square inch of surface on a computer disk. This is about 30 times as much information as can be recorded today in IBM’s industry-leading disk drives, which store data at densities of about 350 million bits per square inch. The scientists described a practical new way to generate a large increase in the electrical resistance of a multilayered metal as it moves near a tiny spot of magnetic material. This will allow computer HDDs to detect weak magnetic fields produced by very small spots that represent information in future gens of disk storage devices. Use of the giant magnetoresistive effect in computer disk drives would be an extension of the M-R head technology used in today’s advanced disk drives to read information stored on magnetic disks. Pioneering work in understanding the physics of the giant magnetoresistive effect has been done by scientists at IBM’s Almaden.

With the switch from inductive head to magnetoresistive head technology, the density with which magnetic information can be stored is now doubling every 18 months instead of every two and a half years. The giant magnetoresistive effect offers a promising way to continue this accelerated growth rate for a longer time.

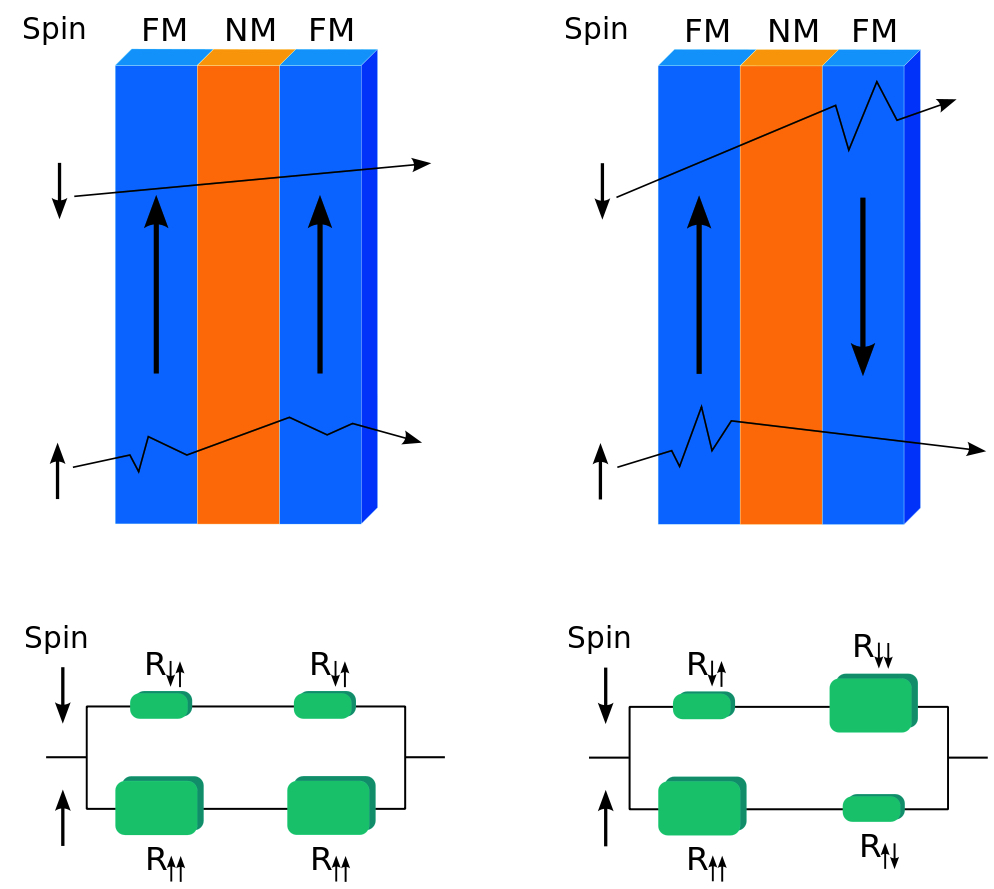

Magnetic field causes changes in electrical resistance Magnetoresistance means that certain materials change their electrical resistance when they are in the presence of a magnetic field. Information in magnetic disk drives is stored as small magnetized spots on the surface of rotating disks. These magnetized spots generate very small magnetic fields in their vicinity. The fields are detected by a nearby sensor called a head, which skims over the surface of the rotating disk. When a magnetoresistive head passes over a magnetized spot, the associated magnetic field causes its resistance to increase, generating an electrical signal that can be interpreted as a bit of information. As the magnetic spots representing information on a disk get smaller and smaller in each succeeding gen of technology, it becomes harder and harder to detect them, and the heads become more and more difficult to fabricate.

In the work reported by the IBM scientists, the magnetoresistive effect produced an electrical signal times as strong as that produced by heads based on conventional magnetoresistive technology. Because of the stronger signal, heads produced with materials exhibiting the giant magnetoresistive effect should be able to detect magnetic spots that are much smaller and more densely packed than those in current products. This will make it possible to push the limits of magnetic storage technology.

Giant magnetoresistive effect

While the giant magnetoresistive effect was originally observed by other scientists, the current results represent the first time it has been observed at very small magnetic fields (typical of those produced by magnetic disks) with the aid of simple sensors. The sensors were fabricated as stacks of thin layers of alternating magnetic and non-magnetic materials, each about 2 billionths of a meter thick. (500,000 of these layers would be about as thick as a sheet of typing paper.)

In the structures fabricated by the scientists, magnetic layers of a nickel-iron alloy were interleaved with non-magnetic layers made of silver. All layers were produced by a commonly used thin-film fabrication process known as “sputtering,” in which ions bombarding a target material dislodge atoms that fall onto a substrate at precisely controlled rates.

Annealing aligns magnetic poles in multi-layered metals

In order for the multi-layered structure to be effective in detecting small magnetic fields, it was necessary to find a way to control the interactions between adjacent magnetic layers. Specifically, it was necessary to make the north poles in one layer point in the opposite direction from the north poles in adjacent layers. The scientists were able to make this occur by heating the completed structures in a furnace – a process called annealing. When the annealed structure is placed in a magnetic field, the north poles in the magnetic layers flip directions so that all layers have the same magnetic orientation. It is this reorientation of magnetic poles that changes the resistance of the multi-layered material, producing a “giant” signal that indicates the presence of a magnetic field.

The next step in the development of the giant magnetoresistive effect for application in disk drives is to fabricate a prototype head capable of reading information stored on a disk. After that, it will be necessary to optimize the materials and processes needed to mass produce the heads for use in commercial products.

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue 68, published on September 1993.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter