VLSI Symposia: Imec Unveils Manufacturable Solution for Field-Free Switching Operation of Spin-Orbit Torque MRAM Devices

Eliminating need for external magnetic field during write operation

This is a Press Release edited by StorageNewsletter.com on June 19, 2019 at 2:22 pmAt the 2019 Symposia on VLSI Technology and Circuits, Imec International (Interuniversitair Micro-Electronica Centrum) has demonstrated field-free switching operation of spin-orbit torque MRAM (SOT-MRAM) devices – eliminating the need for an external magnetic field during write operation.

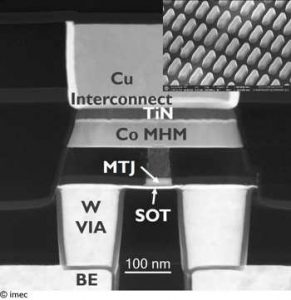

Lateral TEM cross section view of the SOT-field-free switching-MTJ

with Co magnetic hard mask (MHM).

The concept is manufacturing-friendly and does not compromise the reliability and sub-ns writing performance of the SOT-MRAM devices. The new field-free switching concept opens possibilities for the further development of MRAM-based technologies and non-volatile logic and memory applications (such as non-volatile latch circuits and flip-flops).

At the 2018 Symposia on VLSI Technology and Circuits, the company demonstrated the possibility of fabricating state-of-the-art SOT-MRAM devices on 300mm wafers using CMOS-compatible processes. These SOT-MRAM devices are a class of non-volatile memories that, thanks to a high endurance and sub-ns switching speed, can potentially replace fast L1/L2 SRAM cache memories. Writing of the memory elements is performed by injecting an in-plane current in a SOT layer that is adjacent to a magnetic tunnel junction (MTJ). During write operation, a small in-plane magnetic field is required to break symmetry and ensure deterministic magnetization switching. In today’s devices, this is done by applying an external magnetic field, which is recognized as a major hurdle for the practical use of these devices.

Imec has proposed a reliable ‘field-free’ switching concept that consists of embedding a ferromagnet in the hardmask that is used to shape the SOT layer. With this ferromagnet, a small homogeneous in-plane field is induced on the free layer of the magnetic tunnel junction.

“A major advantage of imec’s integrated solution compared to other proposed solutions, is the ability to separately optimize the properties of the magnetic tunnel junction and the conditions of the field-free switching”, explains Gouri Sankar Kar, program director, IMEC. “This ‘de-coupling’ turns our field-free switching solution into a manufacturing friendly concept, which is a major requirement for the high-volume production of SOT-MRAM devices.”

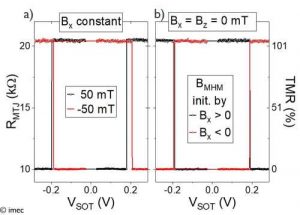

RV curves demonstrating field-free switching:

(a) under large applied in-plane field and (b) at 0 external field.

With writing speeds below 300ps and unlimited endurance (up to 1011 cycles) – measured on multiple devices across a 300mm wafer – the approach is shown to be reliable while preserving the original sub-ns writing of the SOT-MRAM devices.

“This confirms the potential of the SOT-MRAM devices for replacing SRAM at low-level caches”, adds Gouri Sankar Kar. “Moreover, the new field-free switching concept can potentially be applied to other MRAM-based technologies such as spin-transfer torque MRAM (STT-MRAM) and voltage-controlled magnetic anisotropy (VCMA), and opens doors to other non-volatile logic and memory applications such as non-volatile flip-flop and non-volatile latch circuits.”

Future work will focus on further reducing the energy consumption of the SOT-MRAM devices by bringing down the switching current.

About IMEC

Imec is a research and innovation hub in nanoelectronics and digital technologies. The combination of our widely acclaimed leadership in microchip technology and profound software and ICT expertise is what makes us unique. By leveraging its world-class infrastructure and local and global ecosystem of partners across a multitude of industries, the firm creates innovation in application domains such as healthcare, smart cities and mobility, logistics and manufacturing, energy and education.

As a trusted partner for companies, start-ups and universities, the company bring together more than 4,000 brilliant minds from over 97 nationalities. Imec is headquartered in Leuven, Belgium and has distributed R&D groups at a number of Flemish universities, in the Netherlands, Taiwan, USA, and offices in China, India and Japan. In 2018, imec’s revenue (P&L) totaled €583 million.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter