History (1979): Thin-Film Heads Introduced for Large HDDs

Photolithography enables new generation of high-density disk drives.

This is a Press Release edited by StorageNewsletter.com on May 7, 2018 at 2:12 pmThis article comes from the Computer History Museum.

1979: Thin-film heads introduced for large disks

Photolithography enables a new generation of high-density disk drives

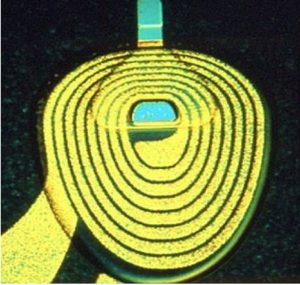

Thin film copper coil on the read/write head of the 3370 and 3380 drives

(Courtesy IBM)

First introduced in 1979 for large disk files on the IBM 3370 Direct Access Storage Unit, thin-film technology enabled new read/write head structures that increased HDD recording densities.

Derived from work at IBM’s Thomas J. Watson Research Center, thin-film processes employed photolithographic techniques similar to those used on semiconductor devices to fabricate disk drive heads with smaller size and greater precision than ferrite-based designs. Successive photomasking, etching, and deposition steps (both in vacuum and by wet plating) built up thin layers of magnetic (Ni-Fe), insulating, and copper coil wiring materials on ceramic substrates that were then physically separated into individual read/write head circuits integrated with their air bearing significantly reducing the manufacturing cost per unit.

The small physical size of the 3370 slider allowed the flying height above the disk to be reduced by nearly 30% from the Winchester design, from 18 down to 13 microinches (320nm), and raised the areal density by a factor of 2x to 7.7Mb per square inch. With seven 14-inch diameter disks, Model 1 versions of the 3370 had a capacity of 571MB. Using similar technology the 3380 shipped in 1981 offered a four-fold increase in capacity.

Together with other advances, increasing the 8 turns of coil wiring employed on the 3370 and 3380 heads to 31 turns, in 1987 the 3380K drive achieved an areal density of 35.9Mb/square inch.

Produced for over 15 years, the 3380 family was one of most successful products in the history of IBM.

Experience with volume production of thin film materials established the foundation for processes, tools, testers, etc. that enabled magnetoresistive (MR) heads to deliver significant HDD areal density increases.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter