R&D: Electro-Thermal Actuator and Lever System Keeps HDD Recording Heads on Track

System achieving milestone in micro-positioning

This is a Press Release edited by StorageNewsletter.com on September 28, 2016 at 2:56 pmAs the density of data stored on a HDD gets close to multiple terabytes per square centimeter, the precision of the internal components is becoming increasingly significant.

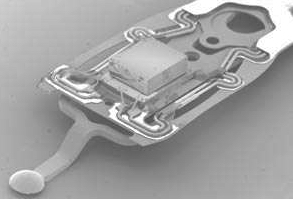

Slider and recording head assembly that writes data to modern HDD drives.

(Credit: IOP Publishing)

A*STAR (Agency for Science, Technology And Research, Singapore) researchers have designed a system that achieves a milestone in micro-positioning, and it could become the next industry standard.

Like a 21st century update of the gramophone record, HDD drives consist of thin magnetic platters with data bits arranged on concentric tracks. The data bits are read and written by a magnetic recording head that floats a few nm above the platter surface at the end of a ‘slider’ arm, while the platter spins at high speed beneath it.

But unlike an old record, a modern disk drive contains up to a million tracks per inch and track widths as narrow as 25nm. And that density is increasing every year. This means future disk drives will require extraordinarily precise head positioning and responsiveness to meet performance expectations.

“The actuator mechanism will need to be able to position the recording head with a precision of just one or two nm,” explains Jiaping Yang, storage Institute, A*STAR. “The actuator schemes commonly used today can offer a fast response, but will have difficulty achieving the positioning accuracy needed for future high-density drives.“

Yang and his colleagues from A*STAR and Nanyang Technological University in Singapore have been investigating the possibility of using an electrically activated thermal expansion element to control the position of the recording head at the end of the slider. The latter provides the larger-scale movement needed to navigate across multiple tracks

Their electro-thermal element is called a thermal unimorph and it consists of a comb-like set of silicon teeth interlaced with polymer expanders.

Yang says: “Silicon has high thermal conductivity but small thermal expansion, while the polymer expander has a large thermal expansion coefficient, but low thermal conductivity. When we resistively heat the element by applying electricity to the silicon, the polymer expands, causing the silicon comb to bend.“

Although the thermal unimorph can be controlled with nm precision, its range of motion was previously too limited to be of practical use. Yang and his team overcame this limitation by adding a rotary lever action that magnified the stroke length by six times.

“We are now exploring possible approaches to improve actuation speed performance, such as designing a more efficient heat path, investigating new thermally active materials, and further miniaturization of the actuator footprint,” says Yang.

Article:

Journal of Micromechanics and Microengineering has published an article written by Gih Keong Lau, Nanyang Technological University, Singapore 637978, Jiaping Yang, Cheng Peng Tan and Nyok Boon Chong, Nanyang, Data Storage Institute.

Abstract: “Slider-level micro-positioners are useful to assist a voice coil motor to perform fine head positioning over a Tb/in² magnetic disk. Recently, a new kind of slider-level micro-positioner was developed using the thermal unimorph of the Si/SU8 composite. It has the advantages of a very small footprint and high mechanical resonant frequency, but its stroke generation is inadequate, with a 50nm dynamic stroke at 1 kHz. There is a need for a larger thermally induced stroke. This paper presents a rotary design of an electrothermal micro-positioner to address the stroke requirements without consuming more power or decreasing the mechanical resonant frequency. Experimental studies show the present rotary design can produce a six-fold larger displacement, as compared to the previous lateral design, while possessing a 35kHz resonant frequency. In addition, simple analytical models were developed to estimate: (i) the rotational stiffness and system’s natural frequency, (ii) thermal unimorph bending and stage rotation, and (iii) the system’s thermal time constant for this rotary electro-thermal micro-positioner. This study found that this rotary electro-thermal micro-positioner can meet the basic stroke requirement and high mechanical resonant frequency for a moving slider, but its thermal cut-off frequency needs to be increased further ”.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter