Flinders University: R&D for New Direction for Data Storage with Polymer

Probe-based mechanical data storage on polymers made by inverse vulcanization

This is a Press Release edited by StorageNewsletter.com on December 30, 2024 at 2:00 pmFrom Flinders University, Australia

A new material for high density data storage can be erased and recycled in a more efficient and sustainable way, providing a potential alternative to HDDs, SSDs and flash memory in future. The low-cost polymer stores data as ‘dents’, making a miniscule code in patterns, with the indents just nanometers in size – promising to store more data than typical HDDs.

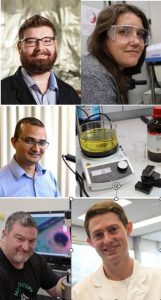

The Chalker Lab research group (clockwise from top left) Flinders University Professor of Chemistry Justin Chalker, Abigail Mann, the raw materials used in the polymer, Samuel Tonkin, Dr Christopher Gibson and Dr Pankaj Sharma, from Flinders University Institute for Nanoscale Science and Technology.

The Flinders University Chalker Lab polymer, which can have the information in it wiped in seconds by short bursts of heat and be reused several times, is described in a major new article in the international journal Advanced Science.

“This research unlocks the potential for using simple, renewable polysulfides in probe-based mechanical data storage, offering a potential lower-energy, higher density and more sustainable alternative to current technologies,” says Abigail Mann, 1st author and PhD candidate, College of Science and Engineering, Flinders University.

Made from low-cost materials, sulfur and dicyclopentadiene, the researchers used an atomic force microscope and a scanning probe instrument to make and read the indentations.

Senior author Professor Justin Chalker says the development is the latest example of new era polymers capable of making a difference to a wide range of industries. “The age of big data and artificial intelligence is increasingly driving demand for data storage solutions,” says Professor Chalker. “New solutions are needed for the ever-growing computing and data storage needs of the information era.”

“Alternatives are being sought to hard disk drives, solid-state drives and flash memory which are constrained by data density limits – or the amount of information they can store in a particular area or volume.”

Using the method, the polymer chemistry team at Flinders University demonstrated data storage densities that exceed typical HDDs.

The polymer chemistry method allowed for the data writing, reading and erasing to be repeated many times, which is important in computing and data storage.

The concept of storing data as indents on the surface of materials has been explored previously by computing giants such as IBM, LG Electronics and Intel. While this mechanical data storage strategy provided some very promising demonstrations and innovations in storage, the energy requirements, costs, and complexities of the data storage materials are some of the barriers to commercialising the technology.

Dr Pankaj Sharma and Dr Christopher Gibson, senior researchers, say the Flinders polymer addresses these challenges with its unique physical structure that allows mechanical force to encode the data via an indentation, and a chemical structure that allows rapid reorganisation of the polymer upon heating to erase that indent.

“The low cost of the building blocks (sulfur and dicyclopentadiene) are an attractive feature that can support future development of the polymer in data storage applications,” adds Samuel Tonkin, Chalker Lab PhD candidate.

Acknowledgements: The project was directed and supervised by Dr Pankaj Sharma, Dr Christopher Gibson and Professor Justin Chalker. Financial support for this research was provided by the Australian Research Council (DP200100090, DP230100587, and FT220100054). Key technical support and instrumentation essential for this research was provided by Flinders Microscopy and Microanalysis (FMMA), Adelaide Microscopy, and the Australian National Fabrication Facility (ANFF).

Article: Probe-Based Mechanical Data Storage on Polymers Made by Inverse Vulcanization

Advanced Science has published an article written by Abigail K Mann, Samuel J Tonkin, Institute for Nanoscale Science and Technology, College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, and College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, Pankaj Sharma, Institute for Nanoscale Science and Technology, College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, and ARC Centre of Excellence in Future Low Energy Electronics Technologies (FLEET), UNSW Sydney, Sydney, NSW, 2052 Australia, Christopher T Gibson, College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, Flinders Microscopy and Microanalysis, College of Science and Engineering, Flinders University, Bedford Park, Adelaide, South Australia, 5042 Australia, and Adelaide Microscopy, The University of Adelaide, Adelaide, South Australia, 5000 Australia, and Justin M Chalker, Institute for Nanoscale Science and Technology, College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia, and College of Science and Engineering, Flinders University, Bedford Park, South Australia, 5042 Australia.

Abstract: “Big data and artificial intelligence are driving increasing demand for high-density data storage. Probe-based data storage, such as mechanical storage using an atomic force microscope tip, is a potential solution with storage densities exceeding hard disks. However, the storage medium must be modifiable on the nanoscale. While polymers are promising storage media, they face challenges with synthesis, erasing temperatures, and stability. Here, a low-cost and robust polymer system is reported that allows repeated writing, reading and erasing. The polymer is made by inverse vulcanization, providing a network of S─S bonds that can be broken and re-formed repeatedly. This property is leveraged in mechanical indentation to encode information, and thermal S─S metathesis and polymer re-flow to erase. Exquisite control of indentation depth is possible over 1–30 nm. This control enables data encoding not just as a function of the presence or absence of an indent, but also indentation depth. This ternary coding increases the data density four-fold over binary coding. Furthermore, the coding can be done at room temperature which is rare for mechanical information storage. The low cost, ease of synthesis, and dynamic S─S bonds in these polymers are a promising advance in polymer storage media for probe-based data storage.“

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter