SK hynix in Volume Production of First HBM3E Memory

Processes up to 1.18TB of data/second, equivalent to processing more than 230 full-HD movies (5GB each), in one second.

This is a Press Release edited by StorageNewsletter.com on March 29, 2024 at 2:03 pmSK hynix Inc. has begun volume production of HBM3E (*), the newest AI memory product with -high performance, for supply to a customer from late March.

The firm made public its success with the HBM3E development 7 months ago.

The company being the 1st provider of HBM3E, a product with the performing DRAM chips, extends its earlier success with HBM3. The firm expects a successful volume production of HBM3E, along with its experiences also as an industry’s 1st provider of HBM3, to help cement its leadership in the AI memory space.

In order to build a successful AI system that processes a huge amount of data quickly, a semiconductor package should be composed in a way that numerous AI processors and memories are multi-connected. Global big tech companies have been increasingly requiring stronger performance of AI semiconductor and the company expects its HBM3E to be their optimal choice that meets such growing expectations.

The latest product is the industry’s best in all the aspects required for an AI memory including speed and heat control. It processes up to 1.18TB of data/second, equivalent to processing more than 230 full-HD movies (5GB each), in a second.

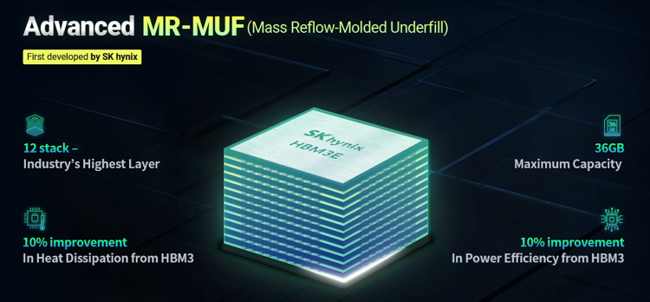

As AI memory operates at an extremely high speed, controlling heat is another key qualification required for AI memories. The HBM3E also comes with a 10% improvement in heat-dissipation performance, compared with the previous gen, following application of the advanced MR-MUF (**) process.

Sungsoo Ryu, head, HBM business, SK hynix, said that mass production of HBM3E has completed the company’s lineup of industry-leading AI memory products: “With the success story of the HBM business and the strong partnership with customers that it has built for years, SK hynix will cement its position as the total AI memory provider.”

(*) HBM (High Bandwidth Memory): A high-value, high-performance memory that vertically interconnects multiple DRAM chips and increases data processing speed in comparison to conventional DRAM products. HBM3E, the extended version of HBM3, is the 5th-gen of HBM following HBM, HBM2, HBM2E and HBM3

(**) MR-MUF (Mass Reflow Molded Underfill): The process of stacking semiconductor chips, injecting liquid protective materials between them to protect the circuit between chips, and hardening them. The process has proved to be more efficient and effective for heat dissipation, compared with the method of laying film-type materials for each chip stack. SK hynix’s MR-MUF technology is critical to securing a stable mass production on the supply side of the HBM ecosystem as pressure on the chips being stacked can be reduced, while warpage control is also improved with adoption of this process.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter