Avalanche Technology Shipping High Density Bootable MRAM Gen 3 Space Grade Dual QSPI Solutions for FPGAs in Space

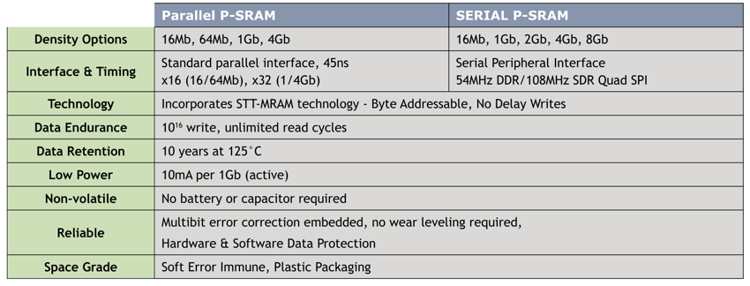

Offered as standard product in density options from 1 to 8Gb, has serial bus interface with byte addressability with no wear leveling.

This is a Press Release edited by StorageNewsletter.com on January 18, 2023 at 2:01 pmAvalanche Technologyy, Inc. announced the availability of their anticipated Gen 3 Space Grade Dual QSPI solutions, now shipping in pre-production.

Click to enlarge

Based on the company’s latest generation of Spin Transfer Torque Magnetoresistive RAM (STT-MRAM) technology, this 3rd-gen product family offers density, endurance, reliability, and power benefits, over existing memory solutions for aerospace and defense applications, particularly for configuring advanced SoCs and FPGAs, which are known to present complex design challenges.

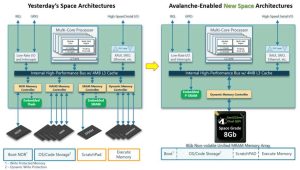

As processing requirements rapidly increase through infrastructure modernization of defense and satellite systems, challenges associated with lagging environment-appropriate memory technologies have handicapped realizable advancement of these systems. This dynamic is heightened when configuring and supporting advanced SoCs and FPGAs for these environments such as AMD (Xilinx) Versal and UltraScale+ ACAP platforms, now approved for use in space and being widely adopted by this community for AI acceleration. Platforms like these would have historically relied on cumbersome memory subsystem partitioning using a combination of PROMs, NOR Flash and SRAM, each with its own required radiation mitigation schemes, resulting in bloated, complex, and expensive designs that extend design and qualification time.

Hailed by the community as the ‘silver bullet’ for this ‘boot module’ application, the firm’s gen 3 Space Grade Dual QSPI device family enables consolidation of historically complex partitioning to that of a singular device(s), capable of reliably configuring advanced FPGAs and SoCs with large image sizes and real time operating systems (RTOS), while also providing support as working memory. Layered onto the core differentiation of the company’s gen 3 Space Grade P-SRAM (Persistent SRAM) family including benchmark environmental resilience, density, endurance, power, performance, and high reliability, the Dual QSPI products offer additional tailored features to accelerate design and in situ configuration of these advanced processing platforms for maximized system performance.

“With this new product family release, we are providing solutions to long-standing challenges faced by the Hi-Rel community at an unfamiliar pace of innovation”, said Danny Sabour, VP marketing and business development. “By adding tailored interfacing and write protection schemes to a product platform that can consolidate traditional non-volatile and volatile memory functions alike, this gen 3 Dual QSPI family offers pin compatible scalability of density and orbital classification, yielding system platforms that are SWaP-C optimized and versatile.”

Working in concert with industry experts, including resources from AMD (Xilinx) to ensure robustness of the platform solution, Avalanche has rolled out key design enablement deliverables in recent weeks to accelerate evaluation, design, and prototyping of a SWaP-C optimized system implementation. These design support resources include reference designs, models, a quick start guide for booting an AMD (Xilinx) Versal FPGA/ACAP and 2 evaluation board options offered through distribution partner Falcon Electronics, including a plug in card that connects directly to existing VCK190 development kits via its existing Samtec connector.

Gen 3 space grade serial dual QSPI persistent SRAM

The gen 3 Space Grade Dual QSPI series is offered as a standard product in density options from 1 to 8Gb and has a serial bus interface with byte addressability with no wear leveling. Designed for high reliability with multibit error correction and 1016 write cycle endurance, data is always non-volatile. The devices are offered in compact 96-ball FBGA (20x20mm) packages with -40°C to 125°C operating temperature range and a JEDEC qualification flow, where every device goes through a 48-hour burn in before being shipped to customers. There are additional qualification screening options available through partners.

Resources:

Resources:

More about our SWAP-C optimized solutions

Why MRAM has a clear advantage in Space applications (registration required)

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter