History (1994): IBM’s Head, Platter and HDD Manufacturing Plant in Mainz, Germany

Output exceeds yearly $1 billion.

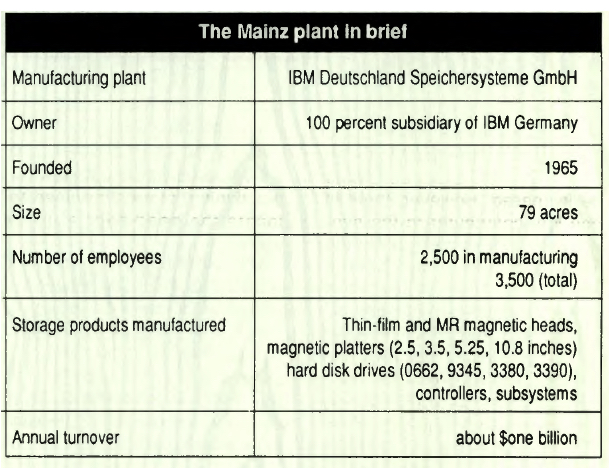

By Jean Jacques Maleval | January 20, 2021 at 2:06 pmIBM’s manufacturing plant in Mainz, Germany is the only one in Europe that simultaneously manufactures magnetic heads (thin-film and MR), platters and disk drives.

But, like all European storage product plants, its main concern is profitability compared to Asian factories.

This plant, along the Main river, 2 miles from downtown Mainz, is one of IBM’s fifth largest ones in the world for storage products, with the San Jose and Rochester ones in the US, the Fujisawa one in Japan and the recent Thailand one with subcontractor Saha Union.

As usual, it’s difficult to get exact figures from IBM.

“Output exceeds $1 billion for the year. We manufacture many hundred thousand HDDs, heads and media in millions,” said Dr. Walter Meizer, director of the German plant.

“We are the only disk and head manufacturer in Europe to my knowledge,” adds Klaus Wattrodt who took us through the plant.

The factory began production on May 2, 1966 with 400 employees. First, it manufactured mid-range CPUs, disk storage products and their controllers as well as R/W heads. Today, on 79 acres, it employs about 3,500 people with close to 1,000 in customer engineering, education, marketing and information service control center, and about 2,500 in manufacturing only. Meizer includes in this last category thin-film and magneto-resistive heads, magnetic thin-film disks, HDAs, power supplies, software development and maintenance, consulting and service.

Three classes of clean rooms are being used in Mainz: 100,000, 10,000 and 100.

Meizer is aware of the difficulty of establishing in Europe. “Germany is not the cheapest place to manufacture. We have to compensate with automation. In the long term, low labor can be avoided since miniaturization will reach a point where human fingers will be too big and automation will be necessary. We base our future on technology, not on assembly.”

Mainz quit making 14-inch magnetic platters, and is going to stop 10.8-inch ones at the end of the year, to only focus on 5.25-inch and mainly 2.5- and 3.5-inch media.

“To OEMs, we don’t sell our own platters, we only manufacture according to required specs.”

No OEM is named in this segment. The only confirmation that was given is that the French firm Nomaï is a customer for its 5.25-inch SyQuest-compatible cartridges.

No price was released.

“The market’s sales price is $12 to $15 for a 3.5-inch platter and the margin is 20 to 30% in the component business,” we were only told.

On their side, MR heads manufactured in Mainz are not for sale.

“On the contrary, we shipped thin-film heads in Southeast Asia,” adds Meizer.

Mainz engineers are working on the prospect of making silicon wafers with the help of the French firm Silmag with whom IBM has recently signed an agreement.

The automation of the Mainz plant seems more advanced than in Havant, UK, mainly for HDAs and the drive assembly. But on the other side, the inspection room for suspensions of the heads seems very labor intensive, with many employees working on a microscope to compensate the robot work that is not efficient enough.

A large part of the disk drive manufacturing involves the 1GB 3.5-inch 0662 model. Here, robotization is extremely advanced for assembling.

Almost all parts are originated from Mainz except the electronic cards that come from Italy. The final tests last 24 hours between 0° and 60° Celsius in several cabinets that can contain over 100 drives with an announced MTBF of 800,000 hours.

“We will soon manufacture here 4GB 3.5-inch drives,” added Meizer.

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue 80, published on September 1994.

Note: Manufacturing products inside this IBM’s Mainz plant were sold during an online auction on June 17, 2003.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter