FujiFilm LTO Tape With Magnetic Recording Method Using Millimeter and Terahertz Waves

Will see magnetic tapes with 10x current capacities within 5 to 10 years.

This is a Press Release edited by StorageNewsletter.com on December 23, 2020 at 2:40 pmDespite challenging market conditions the usage of FujiFilm Corp.‘ LTO tape in Australia has grown steadily over the past year as the technology behind magnetic tapes has continued to improve and become more efficient.

LTO-8 tape

As a result, according to Shin-ichi Ohkoshi, professor, University of Tokyo, the latest development in magnetic tape technology will see magnetic tapes with 10x the current capacities within 5 to 10 years.

In the era of big data and the IoT, is a key technology. From this viewpoint, magnetic recording tapes are used in cloud services and data archives for business purposes because they guarantee long-term storage, low power consumption, and low cost. Consequently, the demand for magnetic recording tapes is growing.

Though they are slower to access than other storage devices, such as HDDs and solid state memories, digital tapes have high storage densities. More information can be kept on a tape than other devices of similar sizes, and they can also be more cost effective too. So for data-intensive applications such as archives, backups and anything covered by the broad term big data, they are important. And as demand for these applications increases, so does the demand for high-capacity digital tapes.

Shin-ichi Ohkoshi, professor, department of chemistry, University of Tokyo, and his team have developed a magnetic material which, together with a special process to access it, can offer greater storage densities. The robust nature of the material means that the data would last for longer than with other mediums, and the novel process operates at low power. As an added bonus, this system would also be cheap to run.

“Our new magnetic material is called epsilon iron oxide, it is particularly suitable for long-term digital storage,” said Ohkoshi. “When data is written to it, the magnetic states that represent bits become resistant to external stray magnetic fields that might otherwise interfere with the data. We say it has a strong magnetic anisotropy. Of course, this feature also means that it is harder to write the data in the first place; however, we have a novel approach to that part of the process too.“

Magnetic pole flip.

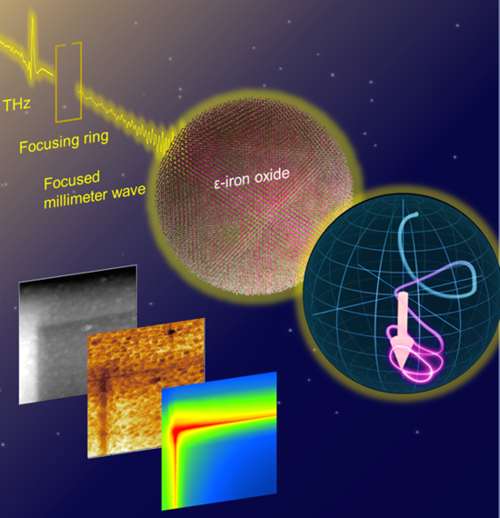

Millimeter waves irradiate epsilon iron oxide,

reversing its magnetic states representing binary states 1 or 0.

© 2020 Ohkoshi et al.

The recording process relies on high-frequency millimeter waves in the region of 30-300GhZ, or billions of cycles per second. These high frequency waves are directed at strips of epsilon iron oxide, which is an excellent absorber of such waves. When an external magnetic field is applied, the epsilon iron oxide allows its magnetic direction, which represents either a binary ‘1’ or ‘0’, to flip in the presence of the high-frequency waves. Once the tape has passed by the recording head where this takes place, the data is then locked into the tape until it is overwritten.

“This is how we overcome what is called in the data science field ‘the magnetic recording trilemma,‘” said Marie Yoshikiyo, project assistant professor, Ohkoshi’s laboratory. “The trilemma describes how, to increase storage density, you need smaller magnetic particles, but the smaller particles come with greater instability and the data can easily be lost. So we had to use more stable magnetic materials and produce an entirely new way to write to them. What surprised me was that this process could also be power efficient too.“

Epsilon iron oxide may also find uses beyond magnetic recording tape. The frequencies it absorbs well for recording purposes are also the frequencies that are intended for use in next-gen cellular communication technologies beyond 5G. So in the not too distant future when you are accessing a website on a 6G smartphone, both it and the data centre behind the website may very well be making use of epsilon iron oxide.

Data center. Digital tapes are very common

in data centers

Wikimedia Commons/Hannes Grobe

“We knew early on that millimeter waves should theoretically be capable of flipping magnetic poles in epsilon iron oxide. But since it’s a newly observed phenomenon, we had to try various methods before finding one that worked,” said Ohkoshi. “Although the experiments were very difficult and challenging, the sight of the first successful signals was incredibly moving. I anticipate we will see magnetic tapes based on our new technology with 10x the current capacities within 5 to 10 years.“

Reference:

Ohkoshi S, Yoshikiyo M, Imoto K, et al. Magnetic-Pole Flip by Millimetre Wave. Advanced Materials. n/a(n/a):2004897. doi:10.1002/adma.202004897

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter