Flexxon eMMC AEC-Q100 Grade 3 and AEC-Q100 Grade 2 Storage Solutions for Automotive Applications

AEC-Q100 Grade 3 supports 40°-85° and AEC-Q100 Grade 2 40°-105° temperature.

This is a Press Release edited by StorageNewsletter.com on August 26, 2020 at 2:29 pmTo support the demand for compact embedded systems across the automotive industry, Flexxon Pte Ltd. has an eMMC storage solution.

The NAND flash technology of the company provides performance, reliability, and enhanced endurance.

The firm manufactures various eMMC devices according to the application requirement. For automotive applications that work within a range of temperature, it offers AEC-Q100 Grade 2 (-40°C~105°C) compliant and AEC-Q100 Grade 3 (-40°C~85°C) compliant. This compact flash storage device also offers power management to give a better automotive experience.

Core objective of automotive eMMC

The eMMC flash storage device has been built to undergo the tough environment of the automobile. Therefore, it acts by TS16949 certification manufacturing, the standard based on ISO 9001. It includes the requirements for the automotive sector to enhance the design/development, production, installation, and servicing of all automotive-related products.

Click to enlarge

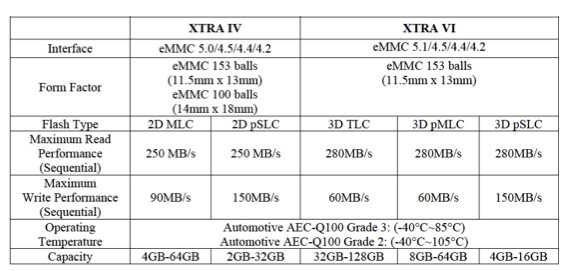

The firm has 2 series automotive-grade eMMC. XTRA IV series supports both 153 balls and 100balls with eMMC 5.0, 4.5, 4.4, and 4.2 interfaces, and XTRA VI series support 153balls only with eMMC 5.1, 4.5, 4.4 and 4.2 interfaces. The eMMC XTRA IV offers 2D MLC and 2D pSLC options and XTRA VI offers 3D TLC, 3D pMLC and 3D pSLC options. The incorporated 2D pSLC and 3D pSLC solutions offer better endurance and performance for the automotive applications providing ample density for storage and stable performance with frequent data writing aptitude. The 3D pMLC solution supports lower error rates at high temperatures compared to 3D TLC, so it is more reliable at high temperatures.

Features of automotive eMMC

The automotive industry requires quality and the company is serving with the best ensuring durability and reliability feature. Keeping that in mind the automotive-grade eMMC devices are featured with:

-

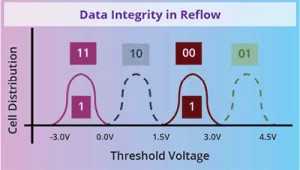

Data integrity in reflow: Leverage strong pages from NAND flash, and prevent data loss in the reflow process.

-

Dynamic Wear Leveling: To keep important data without moving, dynamic wear-leveling could concentrate the write/erase only on the dynamic block.

-

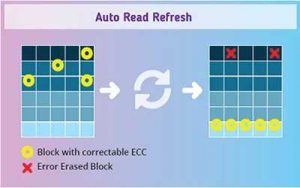

Auto read refresh: Good for read-intensive applications. Firmwares will auto-refresh the bit errors when they are approaching the pre-set threshold level.

-

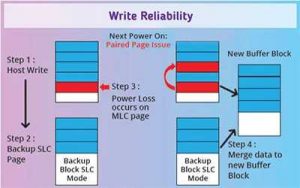

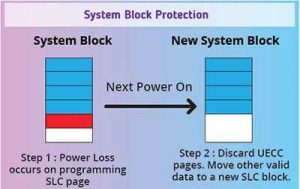

Write reliability: After sudden power loss and next power on, eMMC will scan buffer block until the last programmed page. If ECC Uncorrectable or higher ECC error bit occurs, FW will stop scanning and discard these pages, then copy valid data to a new buffer block to save the data.

-

System block protection: System information is stored in the SLC area for better robustness. During sudden power loss, the FW recognizes data loss in UECC pages. The system block protects those pages from being discarded and moves the valid data into a healthy block.

Applications of automotive eMMC

The company’s automotive-grade eMMC is used in automotive applications, navigation and vehicle infotainment applications such as 3D maps drive recorder, satellite radio, autonomous drive OS and Apps, telemetric and traffic monitoring. It can work in a harsh environment. It makes sure the application performs better within the upgraded technical support, extended life, and stable roadmaps.

eMMC storage design is profound and does not require any other solution to function. The following specs emphasize on longer product life, special capacity in customized memory solution, stronger technical support, and fixed BOM for a complete automotive-grade eMMC:

Read also:

Flexxon: Flash-Based Storage Solutions for Medical Applications

With industrial grade memory devices

May 28, 2020 | Press Release

Flexxon FxAlp USB Flash Module Solution to Ensure Security for Industrial Storage

With AES encryption, built with industrial-grade components and conformal coating on PCB, temperature between -40°C to 85°C

March 30, 2020 | Press Release

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter