History (1993): Calluna, Last European Chance in HDDs?

First products in 1.8-inch form factor

By Jean Jacques Maleval | August 25, 2020 at 2:31 pmThe Scottish start-up Calluna, created by former executives of Rodime, is maybe the last chance for Europe to still exist and not only be a factory land for screw driver assembling for foreign countries.

Calluna’s first product: 85MB on 2 platters, in a 1.8-inch form factor, 10.5mm high. It won’t stay a record for long. Maxtor has just announced a 105MB unit in the same form factor. And this product from Maxtor could interest… IBM.

On its side, MiniStor has just beat a record: a 200G operating shock, still in a 1.8-inch drive. Ever since Rodime, now based in Minneapolis, MN had given up Winchester drive manufacturing to focus on the sale of its patents, there were no more European manufacturers.

There are plants on the continent, but they all are under the control of non-European companies, especially US ones.

Calluna Technology Ltd. (Glenrothes, Scotland) began operations on November 11, 1991, with a team of 6 ex-Rodime employees, led by Norman White, MD, former technical director and one of the founders of Rodime, to develop and manufacture 1.8-inch HDDs.

At the beginning, the money came from private capitals, mainly those of its founders, plus a financial help of the Japanese trading company Kanematsu. The second financial round involved European-only capital ventures, mostly 31 from UK and Innolion SA, the technology investment arm of the French bank Credit Lyonnais (who also invested in Silmag, a planear head manufacturer for Winchester drives). There also are the French Altus Finance SA and Scottish Enterprise.

The amount of the financial investment was not unveiled but could be around “several million pounds” (about $5 million according to the Financial Times, January 21, 1993).

Will this amount of money be sufficient when you know that a start-up company usually needs around $15 million to round up the necessary ingredients to manufacture disk drives in volume, and that most start-ups actually require a third financial round that includes Asian manufacturers?

“We won’t need that much money,” answers White. “Initially we will have our own plant. Maybe, in the future, we may look at an alternative plant in Asia.“

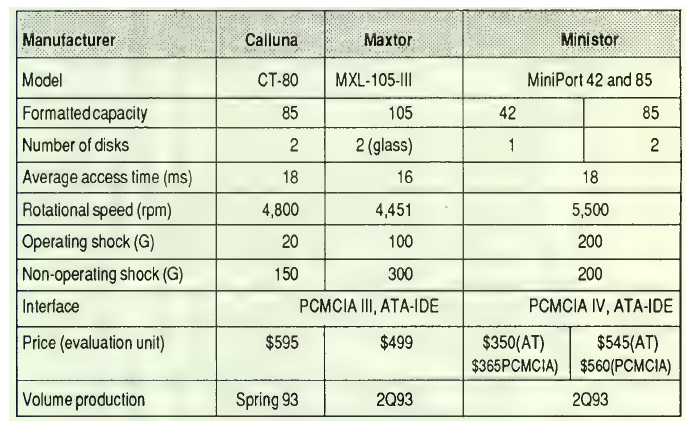

The initial team didn’t try to work in a costly manner. This is a typical Scottish tradition. The company currently employs just 17 people, with two-thirds in product engineering design. Production will start in spring 1993 at Calluna’s 25,000 square-foot facility in Glenrothes which is capable of manufacturing up to 500,000 units per year. A clean room is underway and the company expects to create 100 jobs over this year. Calluna is pursuing ISO 9001 quality certification, scheduled for the end of 1993. The initial product: 1.8 inch, 85MB on 2 disks. The initial product will be the CT-80, a 1.8-inch unit with a formatted storage of 85MB on 2 disks, with an average thickness of 10.5mm, which will allow it to have a PCMCIA Ill removable version. There also will be an ATA-IDE version.

How did Calluna manage to reach such a small height with 2 platters?

“We have patented a combination of many things,” answered White, who doesn’t give any further information as the patent is being filed. “But we use the 4 sides of the disk, thin-film heads and disks, for which we have, for each one, three qualified sources.”

Access time is 18ms, the rotational speed is 4,800rpm. The non operating shock is 150G and the operating shock is a typical 20G (for 11 ms).

“Be careful about shock, it’s not only a number of Gs.”

An evaluation unit, now available, costs $595.

“We don’t know the price of the production units that will be available next April,” said White who adds that no patent from Rodime has been used to develop Calluna’s drives.

We will have to keep an eye on what’s going to happen at Calluna. According to a representative of another French capital venture who did not invest in the Scottish firm, but could in the future: “The market for 1.8-inch drives is tough. Integrators are still hesitant. And it’s difficult to take a position with Hewlett-Packard’s 1.3-inch Kittyhawk. But Calluna has the advantages of being European and having a small structure.”

Disk/Trend nevertheless forecasts that shipments for 1.8-inch drives will rise to 865,000 units in 1993, 2.8 million in 1995. Dataquest mentions 300,000 1.8-inch drives in 1992, 1.4 million in 1993 and 4.8 million in 1994.

“The market for such miniature disk drives is just at its beginning and is projected to exceed $1 billion over the next five years,” stated White.

As of now, competition is strong in the 1.8-inch form factor segment, with several companies involved, like Areal, Aura (with NEC), Conner, Maxtor, Integral, MiniStor, Seagate or Western Digital.

For capacities of 80MB and over, announcements have already been made by Aura Associates (AU 853, 85.3MB, and A126, 126MB) and Integral Peripherals (Cobra 1882P, 85MB). Additionally, Maxtor and MiniStor recently launched interesting products in this form factor. 105MB on Maxtor’s new 1.8-inch drives. At last Comdex/Fall, Aura Associates made a stir by announcing that it would be able, beginning this quarter, to ship 1.8-inch HDDs with capacities of 126MB, a record not reached yet, but its 15mm height doesn’t allow it to conform with the volume required by the PCMCIA Ill slot.

We also noticed on the OEM booth of Adstar, an IBM division, a 10MB disk in “technology display”. And we even were more surprised when we heard, from a reliable source, that this unit came from Maxtor. It’s strange that IBM, who cares a lot for the HDD drive segment, had to get a drive from a competitor to show it like one of its future technologies. And this small unit was in fact the only in ‘technology display’ that was not completely originated from IBM.

Doesn’t Big Blue, actually facing severe financial problems, have the technological resources to face its competitors with its own products? The very few specs given by IBM are exactly the same as those of Maxtor (San Jose, CA) who gives more details on its MXL-105-111: 2 glass platters, 10.5mm high, 70grams, less than 2.0W in R/W mode. The unit, which is a capacity record in the PCMCIA slot volume, is designed to withstand 100G operating shock and 300G non-operating shock by the use of patented design techniques such as shock sensors and ruggedized components. During operation, a sensor anticipates an impending shock or vibration. A special filtration system prevents damage from extreme changes in temperature and humidity. Maxtor announces temperature limits of 5° to 55° in operating mode, and 40° to 70° in non operating mode, relative humidity limits of 5 to 90%, and MTBF of 250,000 hours.

Maxtor even plans to double the capacity of a same size drive before the end of the year.

200G operating on MiniPort from MiniStor

It’s not a capacity record but a shock resistance record in operating mode that MiniStor Peripherals Corp. (San Jose, CA) has just beat: 200G. Its 2 new drives, the MiniPort 42 with 42MB, and the MiniPort 85 with 85MB, 9.8mm and 12.5mm high respectively, have a non-operating shock of 200G, which is becoming common (Maxtor and Seagate reached 300G, Integral S00G).

The company uses a piezoelectric sensor, specially developed, and controlled by a proprietary ASIC, to reach a very short reaction time to a shock on all three axes and in rotational movement. The increased ruggedness is also due to a positive mechanical actuator lock which enables the heads to be parked when the system is turned off. This actuator is attached mechanically to a latch and is stable both when latched and unlatched. MiniStor also incorporated a stuff servo, which is characterized by a high sampling rate (the number of servo patterns per revolution). It prevents the heads from moving off track. There is a trade off, however, with choosing a high sample rate. It increases overhead, which ultimately decreases capacity because more space on disk is occupied by servo data. But MiniStor uses embedded servos (vs. dedicated servo systems), each of the 4 surfaces having servo bursts separated by data fields. To increase ruggedness, the drives also use low mass actuator with nanosliders. They have lower mass and less inertia, providing better shock resistance.

MiniStor even expects to reach 300G in the next 6 months and 400G at mid-94.

How high will we climb in shock protection that is now reaching such points it hardly means anything? But this ruggedness is an important issue in the competition between small disks and flash cards for which manufacturers underline this characteristic.

In addition to Samsung, one of its partners, MiniStor said that Quanta, Acer, EO, Fujitsu, Olivetti, Databook and Toshiba were evaluating its drives for incorporation in notebook or sub-notebook computers.

The small Californian firm had already introduced 32 and 64MB 1.8-inch drives in March 1992 and shipped since 3Q92.

To date, MiniStor has received approximately $14.4 million from investors including Kleiner Perkins Caufield & Byers, Institutional Venture Partners, Grace Ventures, Philadelphia Ventures, New York Life Insurance, Korea Technology Development Corp., and Samsung Pacific.

MiniStor has partnership with:

1/ Zilog (Campbell, CA) for a proprietary version of the Zilog Z8 Microprocessor with a 16-bit digital signal processor,

2/ Technistar (Longmont, CO) for the development and installation of automated production equipment, and

3/ Komag and Dastek for media and thin-film heads.

MiniStor’s 32,000 square foot manufacturing facility is located in Singapore. MiniStor said that its factory is ramping 2,500 drives per day and expects to produce up to 12,000 units daily by 1996.

The latest announcements in 1.8-inch fixed disk drives

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue ≠61, published on February 1993.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter