Picosun ALD Film Coating Solutions Enable Novel High-Speed Memories: Resistance Switching Random Access Memories

Results obtained at Moscow Institute of Physics and Technology for ReRAM non-volatile memory

This is a Press Release edited by StorageNewsletter.com on July 6, 2017 at 2:17 pmPicosun Oy, supplier of Atomic Layer Deposition (ALD) thin film coating solutions, reports of results achieved with its ALD technology in development of novel high-speed memories.

Click to enlarge

These memories are required in state-of-the-art storage applications, where a combination of very large capacity and fast operating speed is needed. The results have been obtained at the company’s long-term customer Moscow Institute of Physics and Technology (MIPT), Russia.

ReRAM (Resistance Switching Random Access Memory) is a non-volatile memory type which has the attributes to become the much sought-after universal memory to replace and outperform the current technologies, and to solve the ever-growing demand for more and more efficient storage systems. ReRAM is fast, small, structurally simple, it has high capacity and it operates at low voltages. These features help to decrease the device size, power consumption, and response time, allowing yet smoother-operating electronic end products. Smaller operating voltage enables ReRAM integration also to low-power devices such as portable, wearable, and mobile electronics, remote sensing and IoT applications, the number of which is growing explosively at the moment.

This far, achieving exact control over the elemental structure of the functional layers in the ReRAM memory cell has been one of the technology’s key challenges. ALD is a method to solve this challenge, in reaching the controllable growth of oxygen deficient oxides, as with ALD the manufacturing process can be fine-tuned and digitally controlled with atomic level precision. Further, ALD is already a production-proven, mature technology in semiconductor industries and thus simple to integrate into existing process flows.

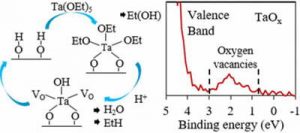

“We are very pleased with the performance of our Picosun ALD system. With it, we can deposit the critical material layers of our ReRAM structure with precision that allows atomic scale control of their chemical composition. We have used our Picosun system for years and achieved several breakthrough results with it. Specifically, Picosun plasma tool allowed us to achieve a robust ALD process for depositing an oxygen-deficient TaOx film based on plasma-activated hydrogen as the reactant and the alkoxide compound Ta(OC2H5)5 as the Ta precursor, which already has a Ta-O bond in it. In this approach, the critical idea is to remove the C2H5 groups by forming volatile C2H6 or C2H5(OH) molecules via the reaction with plasma-activated hydrogen(*). The Picosun system is also very flexible yet extremely reliable. A further asset is the inbuilt upscalability of Picosun’s ALD technology – successful R&D results can be readily transferred to production in a larger, industrial-scale PICOSUN equipment,” says Dr. Andrey Markeev, principal research scientist, MIPT nanotechnology center.

“We have been working with MIPT for a long time so we are extremely pleased that our system has enabled their cutting-edge results in ReRAM technology. Our industrial customers include several leading memory manufacturers, and it is exciting to be a part in the development of yet more advanced storage solutions. These will enable a whole new family of microelectronic products to improve our everyday lives, safety, and ways of communication,” continues Juhana Kostamo, MD, Picosun.

The company provides advanced ALD thin film coating technology to enable the industrial leap into the future, with production solutions and expertise in the field. Today, ALD equipment are in daily manufacturing use in numerous major industries around the world. Picosun is based in Finland, with subsidiaries in Europe, North America, Singapore, Taiwan, China, and Japan, and a worldwide sales and support network.

Video: What is ALD?

Article: In Situ Control of Oxygen Vacancies in TaOx Thin Films via Plasma-Enhanced Atomic Layer Deposition for Resistive Switching Memory Applications

Applied Materials and Interfaces has published an article written by Konstantin V. Egorov, Dmitry S. Kuzmichev, Moscow Institute of Physics and Technology, Institutskii Lane 9, 141700 Dolgoprudny, Russian Federation , Pavel S. Chizhov, Chemistry Department, Moscow State University, Leninskie Gory 1, 119992 Moscow, Russian Federation, Yuri Yu. Lebedinskii,Moscow Institute of Physics and Technology, Institutskii Lane 9, 141700 Dolgoprudny, Russian Federation, and National Research Nuclear University, Moscow Engineering Physics Institute, Kashirskoye Shosse 31, 115409 Moscow, Russian Federation, Cheol Seong Hwang, Department of Materials Science and Engineering and Inter-University Semiconductor Research Center, Seoul National University, Seoul 08826, Republic of Korea, and Andrey M. Markeev, Moscow Institute of Physics and Technology, Institutskii Lane 9, 141700 Dolgoprudny, Russian Federation.

Abstract: “The plasma-enhanced atomic layer deposition (PEALD) process using Ta(OC2H5)5 as a Ta precursor and plasma-activated hydrogen as a reactant for the deposition of TaOx films with a controllable concentration of oxygen vacancies (VO) is reported herein. The VO concentration control was achieved by varying the hydrogen volume fraction of the hydrogen–argon mixture in the plasma, allowing the control of the leakage current density in the tantalum oxide films within the range of 5 orders of magnitude compared with the Ta2O5 film grown via thermal ALD using the identical Ta precursor and H2O. Temperature-dependent current–voltage measurements combined with Poole-Frenkel emission modeling demonstrated that the bulk trap depth decreases with the increasing hydrogen volume fraction, which could be attributed to the increase of the VO concentration. The possible chemical change in the PEALD TaOx films grown under different hydrogen volume fractions was confirmed by the in situ X-ray photoelectron spectroscopy (XPS) measurements of the Ta 4f core and valence band spectra. The comparison of the XPS-measured nonstoichiometry and the secondary ion mass spectrometry analysis of the hydrogen content allowed this study to conclude that the nonstoichiometry is largely related to the formation of Ta–VO sites rather than of Ta–H sites. Such oxygen-deficient TaOx layers were studied for application as an oxygen-deficient layer in a resistance switching random access memory stack (Ta2O5/TaOx) where the actual switching occurred within the stoichiometric Ta2O5 layer. The bilayer memory stack showed reliable resistance switching up to ∼106 switching cycles, whereas the single-layer Ta2O5 memory showed only several hundred switching cycles.”

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter